Learn how THEMIS Technologies helps multiple industrial companies move their business forward by designing and implementing customised laser welding solutions

Laser welding is a process that uses a laser beam to fuse materials. This laser beam concentrates a large amount of energy on a small area, melting materials in a precise and controlled way. The most commonly used laser sources for welding are fibre solid-state lasers, laser diodes, and ultra-short pulse lasers. This technology is widely used in various industries, including automotive, aerospace, electronics, watchmaking, and medical device manufacturing. Laser welding can also be used for high-precision welding applications, such as micro-welding of electronic components and soldering of very thin parts.THEMIS Technologies designs and integrates your new machine in compliance with the standards governing the use of lasers.

Increase the power of your industry with laser welding

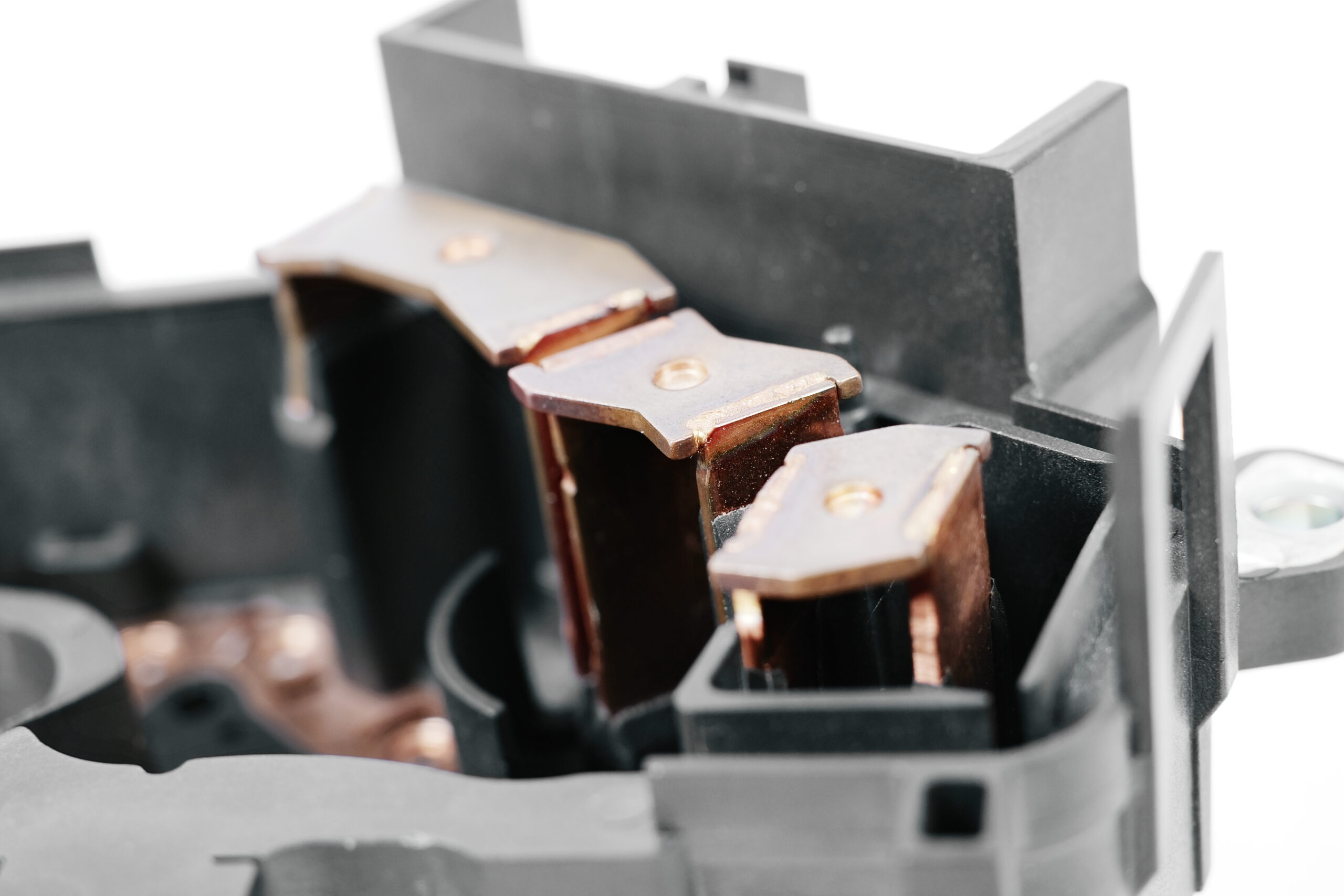

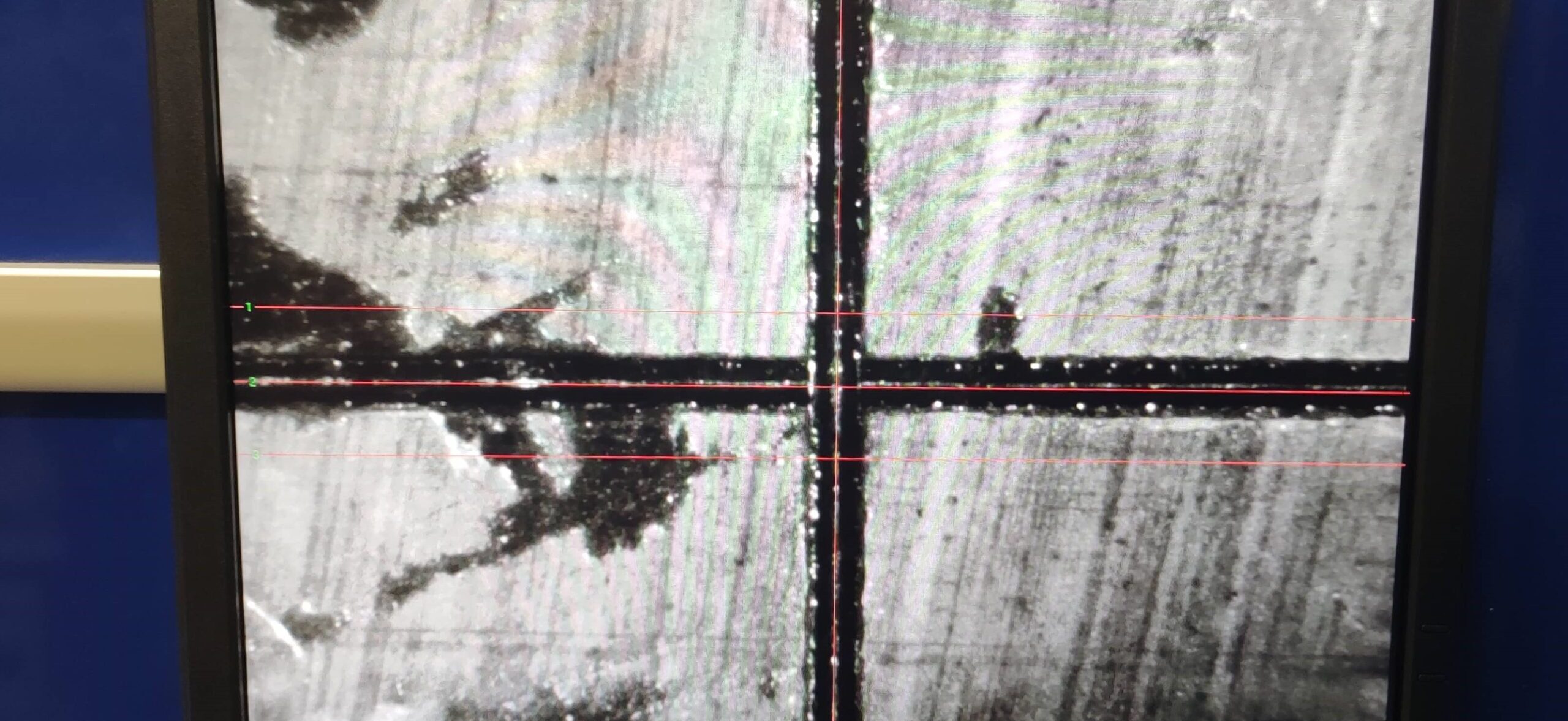

Take your production to the next level by integrating a laser machine on your production line for welding your parts. Laser technology offers one of the fastest execution speeds in the industrial world. The increase in production speed does not compromise on quality or precision: laser welding provides a particularly aesthetic weld. Its thermally affected area is considerably reduced compared to other welding technologies and makes it ideal for micro-welding and the welding of fragile components. This aspect also protects materials by limiting the risk of deformation. In order to optimise your production line, the laser welding process can be automated with a robotic arm.

Contrary to preconceptions, laser technology can save money. Admittedly, the integration of such a machine requires an initial investment. But, by installing a laser welding station on your production line, you will purchase fewer consumables, and shorten the essential preparation, machining and adjustment stages required by other traditional welding technologies.

Post-welding treatments (cleaning, polishing, heat treatment, etc.) are also reduced. You improve your production at no additional cost in the long run.

Laser welding for a strong and durable weld

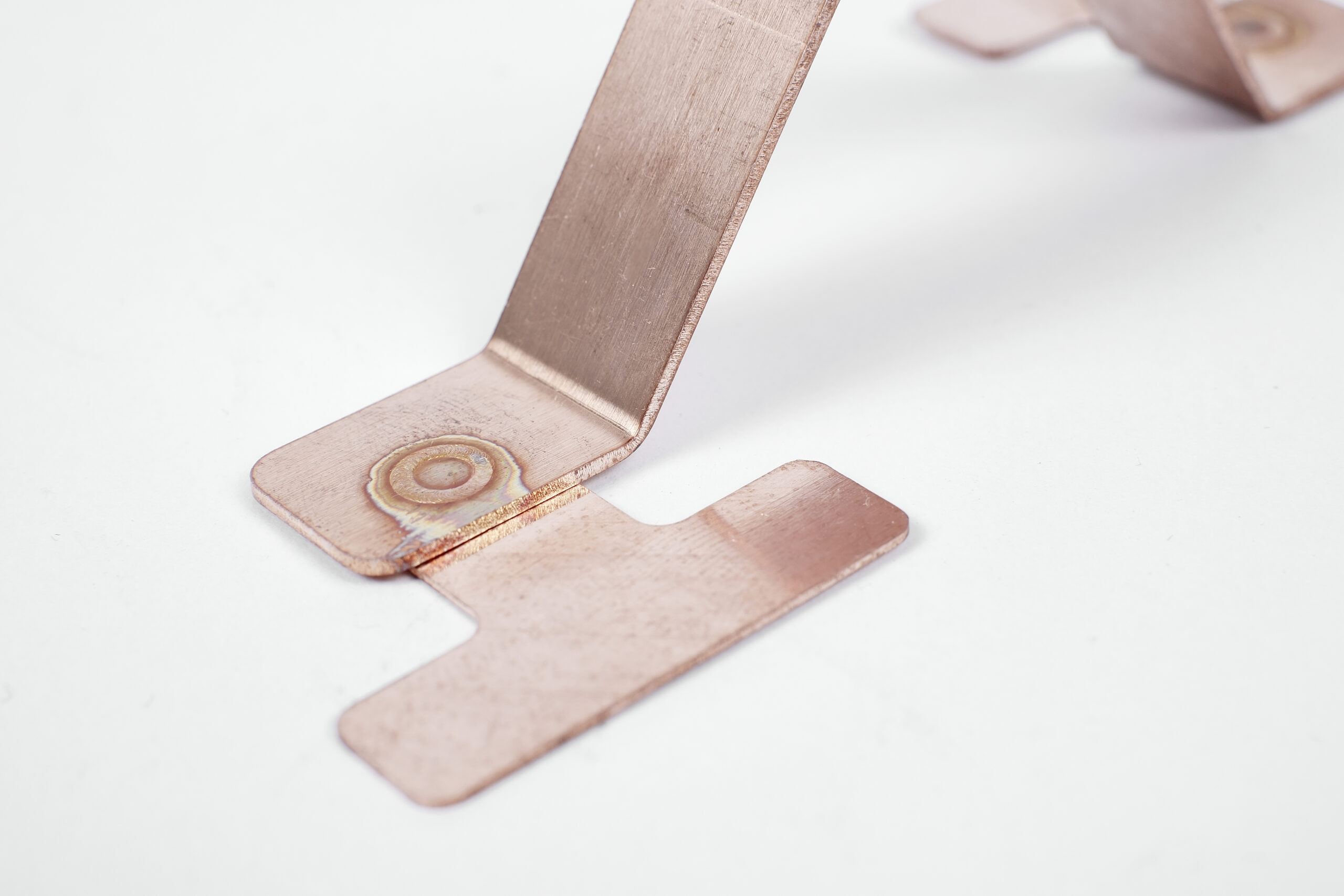

A clean weld is not enough to make it durable. The quality of laser welding also stems from its robustness. The material is melted by the heat given off by the laser beam, which makes it possible to solidly fuse the materials. By the very nature of the process, with tight control of the penetration of the beam, the weld produced has a high mechanical strength. Laser welding is said to be autogenous: no additional material is required to perform the weld. However, it does not exclude it: in some cases, an automatic supply of material is possible.

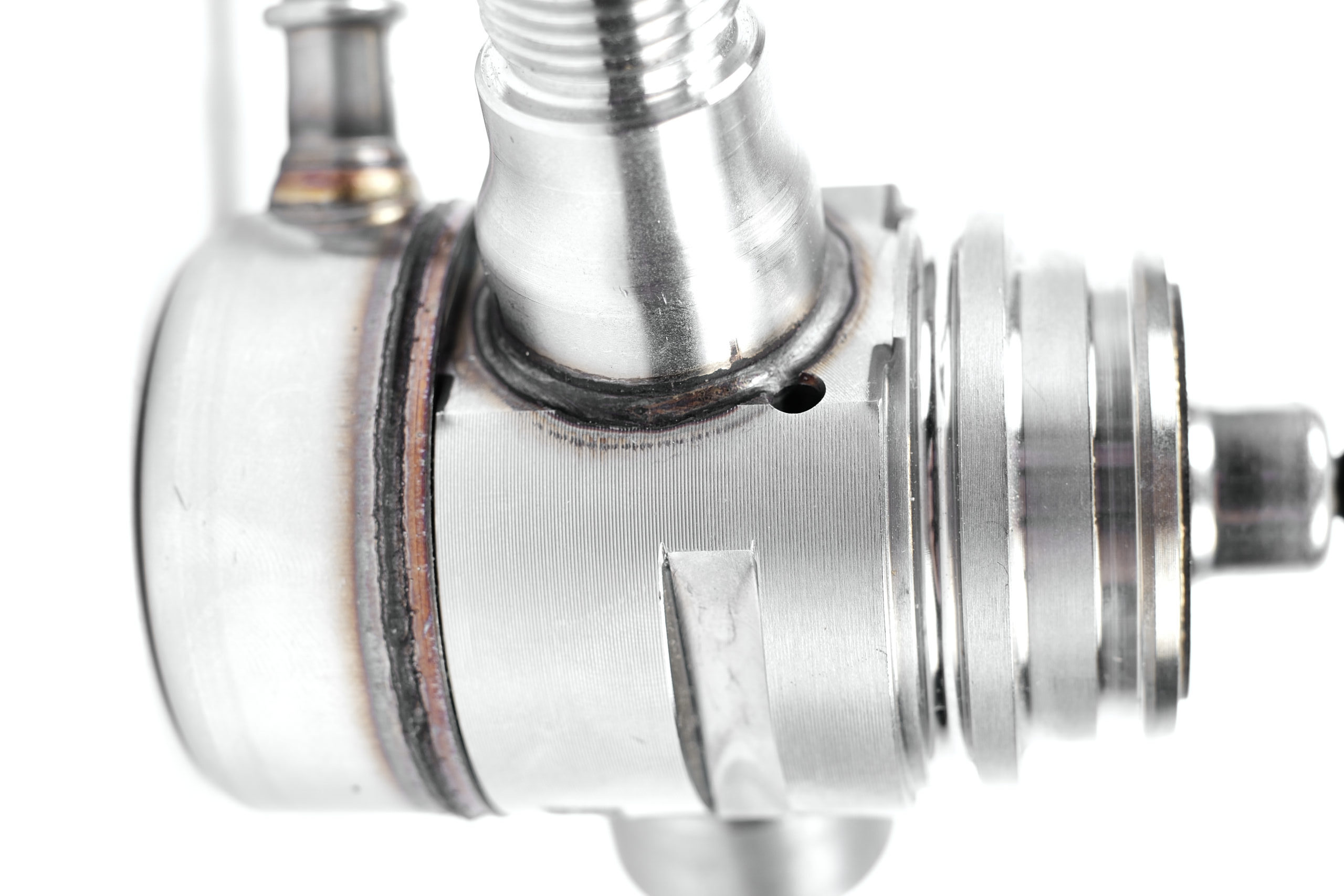

Laser welding offers a perfectly sealed weld, sought after by many industries.

Laser: highly compatible welding technology

Laser technology offers significant versatility to industries working in particularly demanding environments.

The precise configuration of laser technology opens up many possibilities in terms of materials to be welded: steel, aluminium, copper, titanium, or even plastics and glass.

To produce implantable medical devices, for example, cleanroom soldering is essential. This helps reduce the presence of particles, which can contaminate parts. The autogenous aspect of the laser weld allows perfect biocompatibility.

With laser welding, you take your production to a new dimension: faster, more precise and stronger. THEMIS Technologies brings its business expertise to support you in achieving your new goal.

Documents to download

Download our comparison of laser and traditional welding solutions

Contact an expert

Contact our laser expert for any questions.

M. Michel DIOCLES

+33 661 445 098What types of laser are used for laser welding?

What needs to be taken into consideration when laser welding?

Is laser welding suitable for all welding applications?

What are the limitations of laser welding?

What are the other laser applications in the industrial field?