Why choose laser technology to optimise industrial traceability ?

To meet increasingly stringent standards, established to guarantee safety and quality at all stages, the industrial world must deploy solutions that leave no room for approximation.

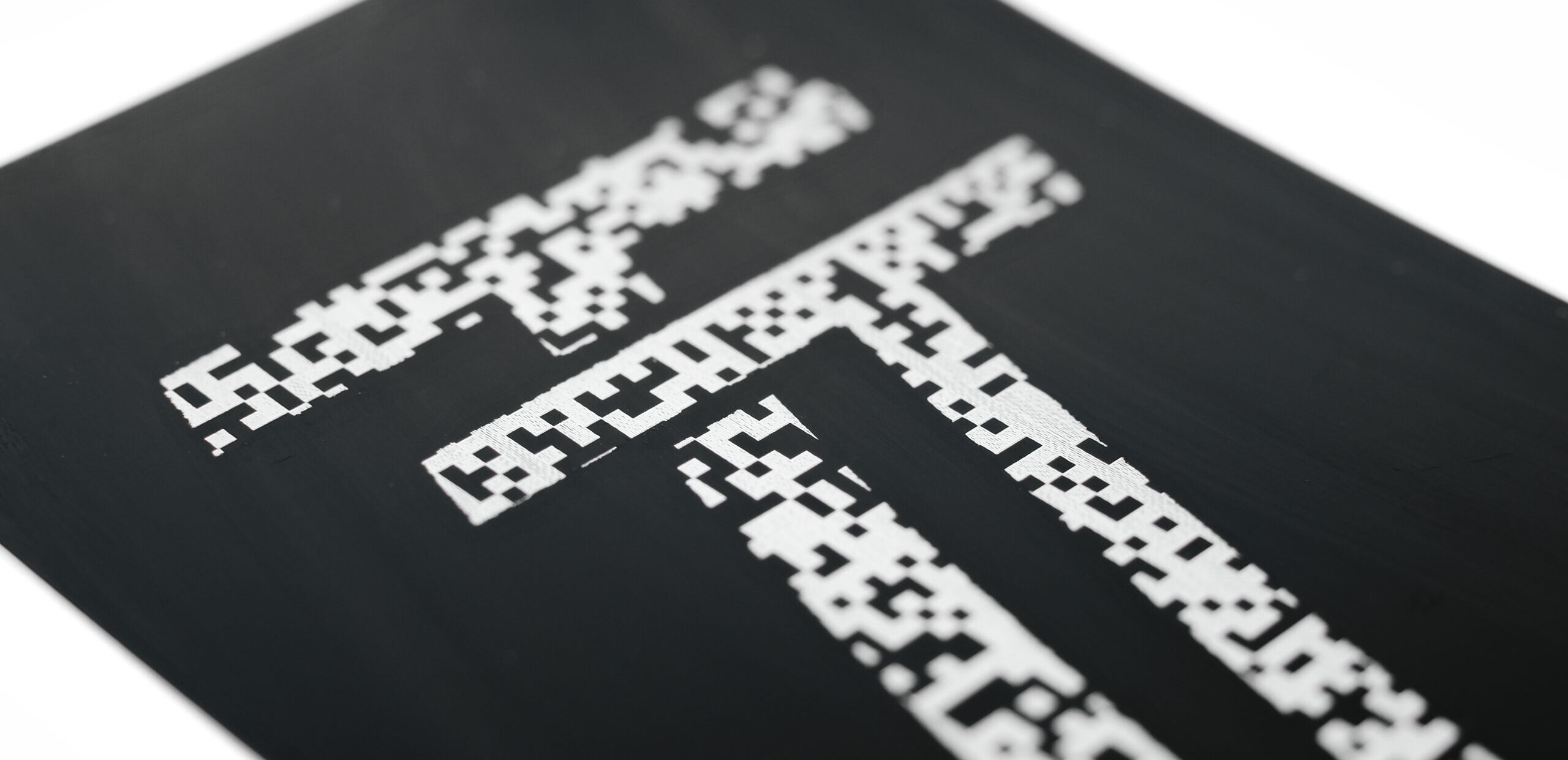

Precise and indelible laser marking

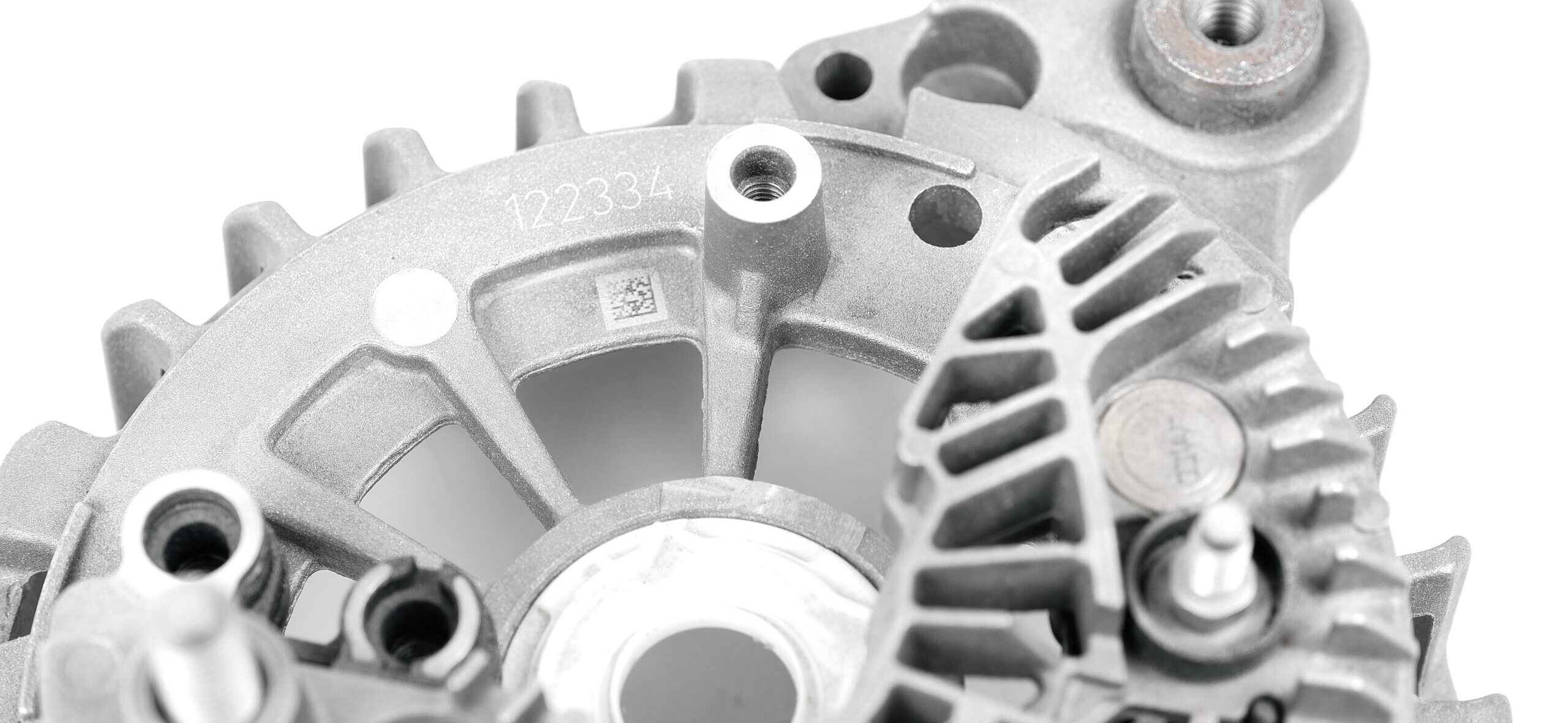

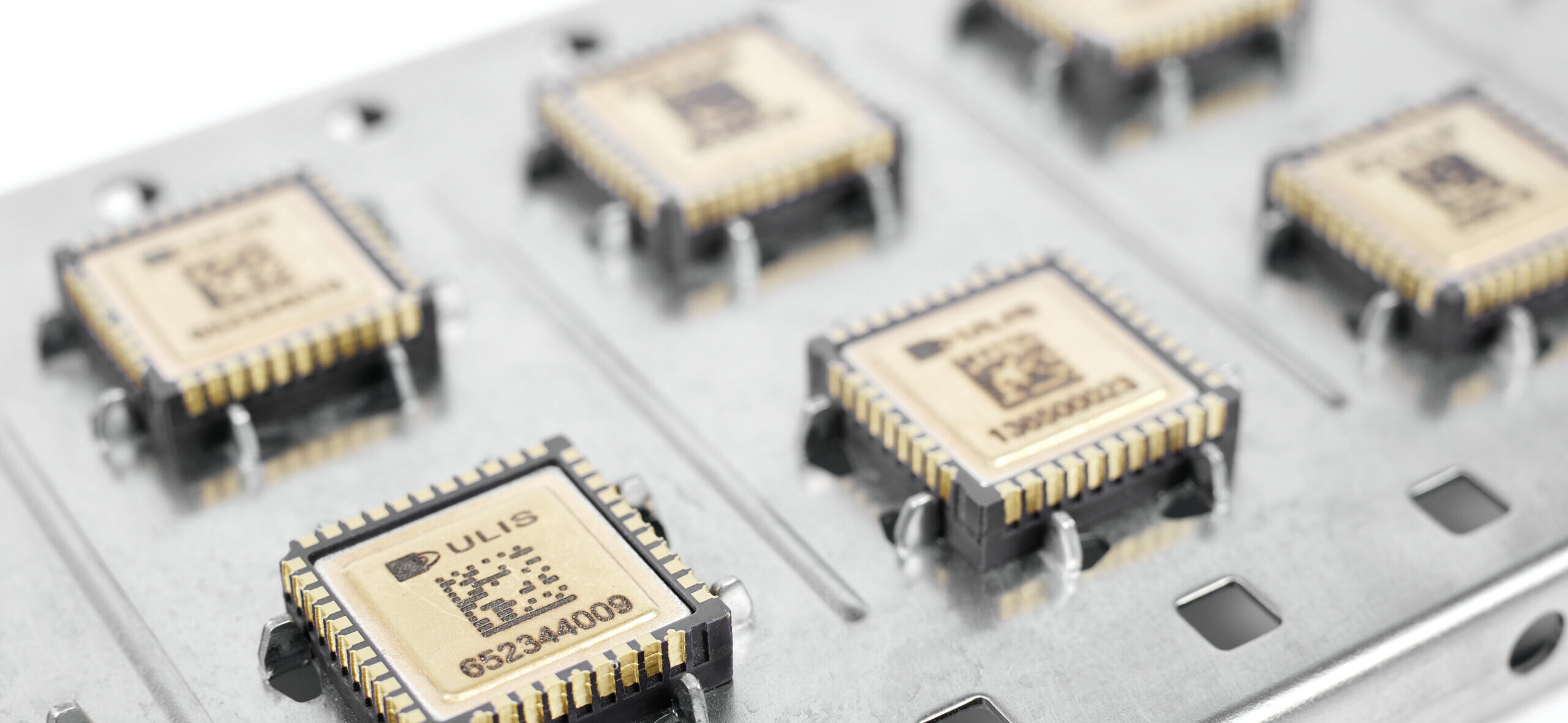

No technology matches laser in terms of breadth of size and durability of markings. It allows direct marking on the product, regardless of the material and without the use of a transfer medium, which reduces operating costs as well as guaranteeing the permanence of the code.

Laser technology allows extremely accurate marking, even in small sizes. This makes it ideal for electronic components, for instance, which can have formats that complicate the marking and reading of codes. Unlike ink printing, laser marking is unalterable and requires no inputs: the code remains perfectly readable over time.

Easy reading of traceability information

Vision systems allow contactless reading of traceability information. It is therefore not necessary to have physical contact with the product to access the codes or serial numbers. This makes it much easier to read data in high-speed production environments.

Complete solutions for all stages of traceability

To facilitate the implementation of traceability on your production lnes, THEMIS Technologies can assist you with:

- laser marking,

- code scanning,

- client network interfacing for serialisation,

- the storage, preparation and provision of data.

This provides you with a complete system that supports every step required for standards-compliant industrial traceability.

THEMIS Technologies supports industrial traceability in the most demanding sectors

While each sector must meet strict standards that ensure security throughout the whole chain, some activities require the deployment of specific solutions, given their inherent requirements and constraints. Find out how THEMIS Technologies supports these sectors.

Industrial traceability of the pharmaceutical sector

Industrial traceability plays a crucial role in the pharmaceutical sector. It helps:

ensure the safety, efficacy and quality of medication,

ensure the transparency and compliance of strict regulations in terms of production, distribution and safety.

To meet the significant constraints of the sector, THEMIS Technologies is developing compact modules that allow the serialisation of boxes, bottles or other containers, at high speed.

This allows for easier laser marking of unique Datamatrix codes, their scanning and checking that they match. Configuration via the human/machine interface makes it possible to process multiple formats with a reduced serial changeover time in under 5 minutes.

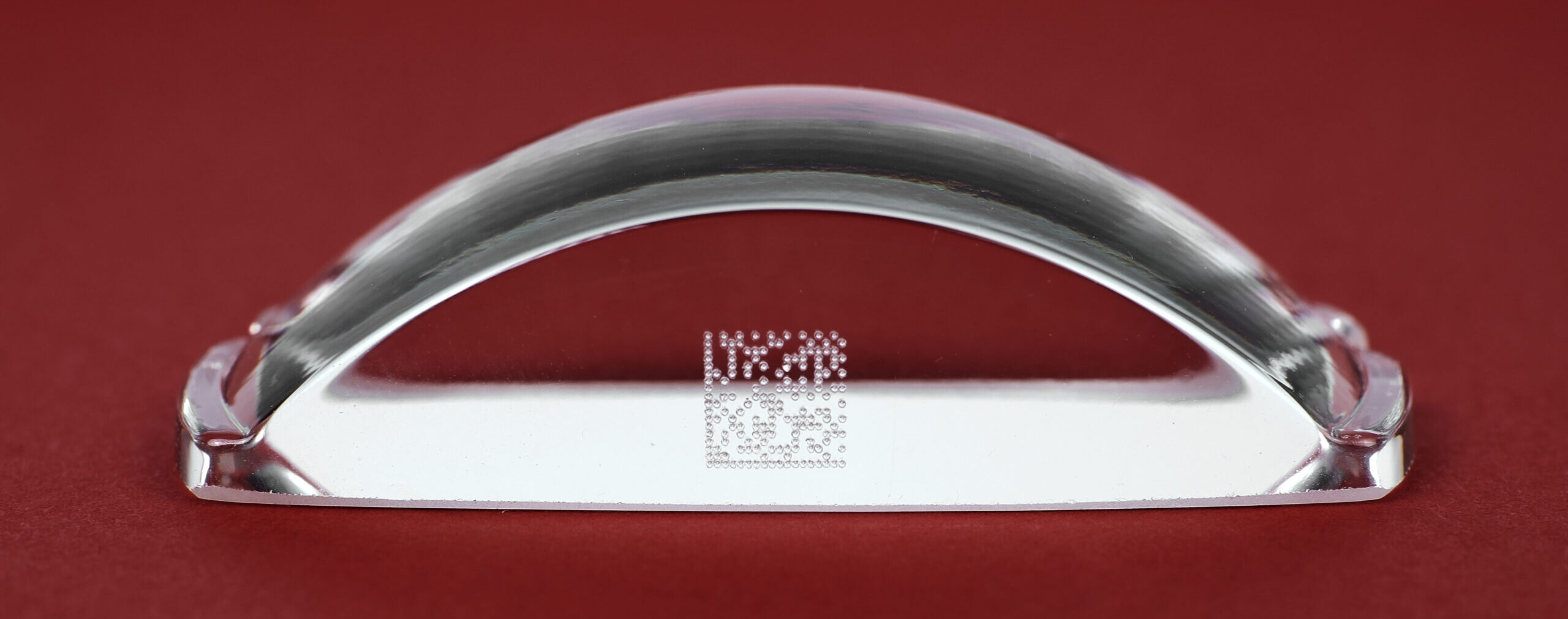

Authentication of luxury goods and cosmetics using laser

In addition to the manufacture and customisation of luxury items (decoration creation, surface texturing, etc.), laser marking supports the industry by offering an authentication solution. The sector is plagued by rising counterfeiting and the presence of a parallel market, especially since the arrival of e-commerce. An IFOP survey for Unifab found that 37% of consumers have already been victims of a counterfeit purchase unbeknownst to them.

Laser marking is used on perfume bottles, powder compacts, lipstick tubes, watches, for instance. By affixing the mark permanently, it is easier to recognise counterfeiting. This process is also used to apply decorations. The fight against counterfeiting also involves the marking of a batch number on items or the application of invisible confidential markings that make it possible to counter parallel markets.

The jewellery sector uses laser marking to guarantee its precious metal products, after clearance with customs. A laser beam can engrave the warranty hallmark with a precision of around one millimetre which cannot be achieved by mechanical hallmarking and without damaging the piece. This process can, of course, be automated. Beyond the warranty hallmark, the laser process can be used to apply the master’s mark, that of the person making the piece.

Laser marking in a hostile environment: the case of traceability in glassware

The traceability of certain products requires marking on hot glass. This material is used in many sectors:

- the food industry with bottles or jars,

- perfumery with bottles,

- pharmaceuticals with vials,

- household products with plates or dishes,

- …

Traceability is essential to identify each bottle or flask, trace all the operations that allowed its manufacture and fight counterfeiting.

The glass manufacturing environment has specific constraints. The heat given off by the furnaces requires manufacturers in the sector to adapt the equipment to difficult conditions, including laser marking modules. Against this backdrop and to meet the demands of glass manufacturers, THEMIS Technologies has designed modules capable of marking hot glass at a rate of 600 products per minute.

Documents to download

Download our comparison on traceability and serialization solutions

CONTACTER UN EXPERT

Contactez notre expert laser pour toute question.

M. François-Eudes LEFEVRE

+33 761 419 057