THEMIS Technologies supports the industry in the design of customised laser solutions. Our goal is to provide a comprehensive response to business needs

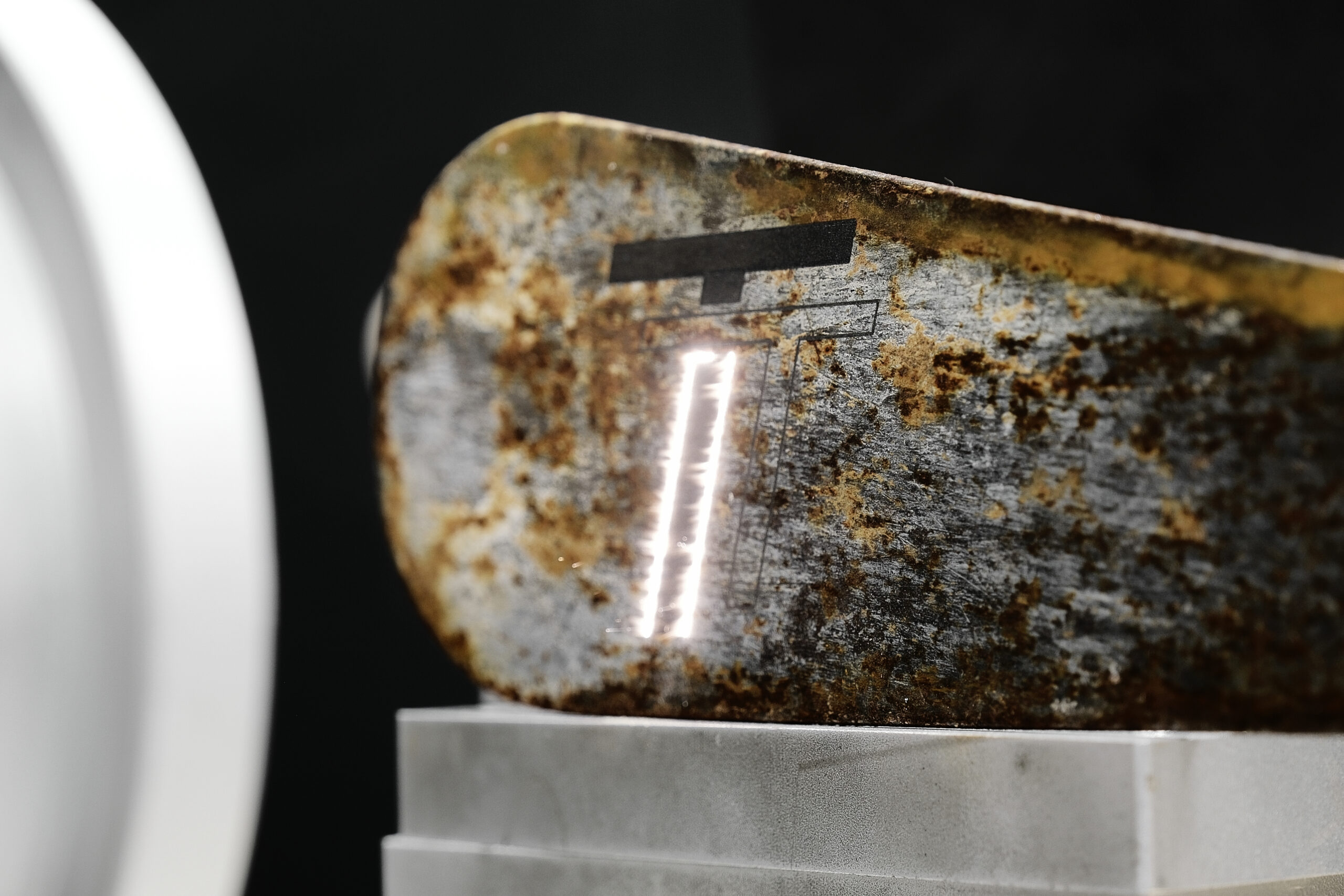

Laser stripping is a cleaning process that involves removing coatings or layers of material (paint, grease, various layers of oxidisation, etc.) from a surface using a laser beam. It is often used as an alternative to traditional chemical or mechanical stripping methods because it offers several advantages. Laser stripping works by focusing a high-energy laser gun on the surface to be treated. The laser beam vaporises or strips the undesirable material, which then comes off the surface as slag or gas. Laser settings, such as power and wavelength, are adjusted according to the desired objective.

Take back control of your cleaning operations with laser stripping

Like all laser processes, stripping provides precise control over the treated area, specifically targeting unwanted coatings or layers without damaging the underlying material. Laser parameters can be adjusted to configure the removal depth, which is particularly useful when only a thin layer needs to be taken from the material. Laser stripping also allows selective cleaning, treating only the desired parts. This technique makes it possible to produce various patterns, for example. The laser beam can access hard-to-reach areas, for optimal cleaning.

Laser stripping thus offers an effective and precise solution for restoring the original appearance of surfaces.

Laser stripping: an indispensable asset for many industries

Integrating laser technology into its production line opens up a wide range of possibilities and takes your business to the next level. This step forward is achievable because laser stripping:

- can be used on many materials,

- allows different types of coatings to be removed,

- optimises various applications in different industrial sectors,

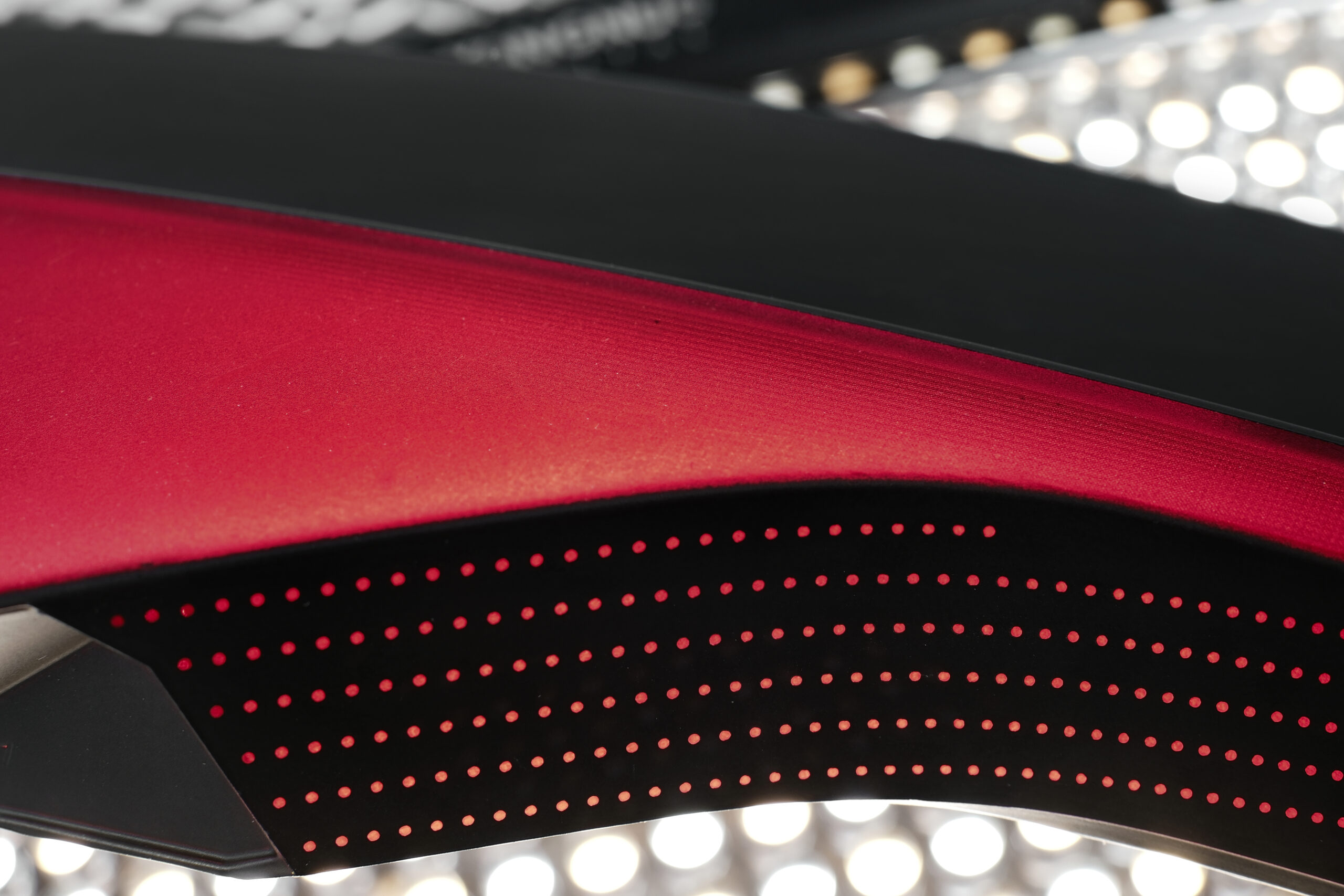

- is automatable with integration on a robotic arm, for example.

In this way, metals, wood, plastics, ceramics, composites and fragile materials such as glass, can be cleaned with the laser stripping technique. It is effective in removing coatings like paint, rust, protective coatings, adhesives, oils, oxides and other surface residues. Automotive, aerospace, electronics, the restoration of objects and heritage conservation are the biggest users of laser stripping.

Reduce your environmental impact with laser stripping

Laser stripping offers an effective cleaning solution while significantly reducing the impact on the environment.

Unlike traditional methods that use, among other things, aggressive chemicals, laser stripping does not need them. This technology eliminates the risk of chemical contamination and reduces the generation of toxic waste. They are easy to store and have no impact on operators’ health.

- By choosing laser stripping, you take a sustainable approach to cleaning,

- by minimising chemical waste, among other things,

- by reducing post-treatment operations (brushing, washing),

- and by maintaining material properties.

Laser cleaning is one of the most environmentally friendly solutions, offering outstanding cleaning results.

THEMIS Technologies meets industrial cleaning needs, by developing turnkey laser machines. Designed to fit seamlessly into their environment, they meet specifications perfectly.

Documents to download

Download our comparison of laser and pyrolysis stripping solutions

Contact an expert

Contact our laser expert for any questions.

M. François-Eudes LEFEVRE

+33 761 419 057Is laser stripping safe?

What are the laser stripping applications?

Does laser cleaning damage the treated surface?

Is the integration of a laser stripping machine expensive?

How long does the laser stripping process take?