THEMIS Technologies supports manufacturers in the design and integration of bespoke laser marking solutions

With our committed team, we develop fully customised machines. We then set them up on your production lines and train you in how to use them. We operate in all areas, such as aeronautics, automotive, cosmetics, pharmaceutical industry, medical or agri-foods.

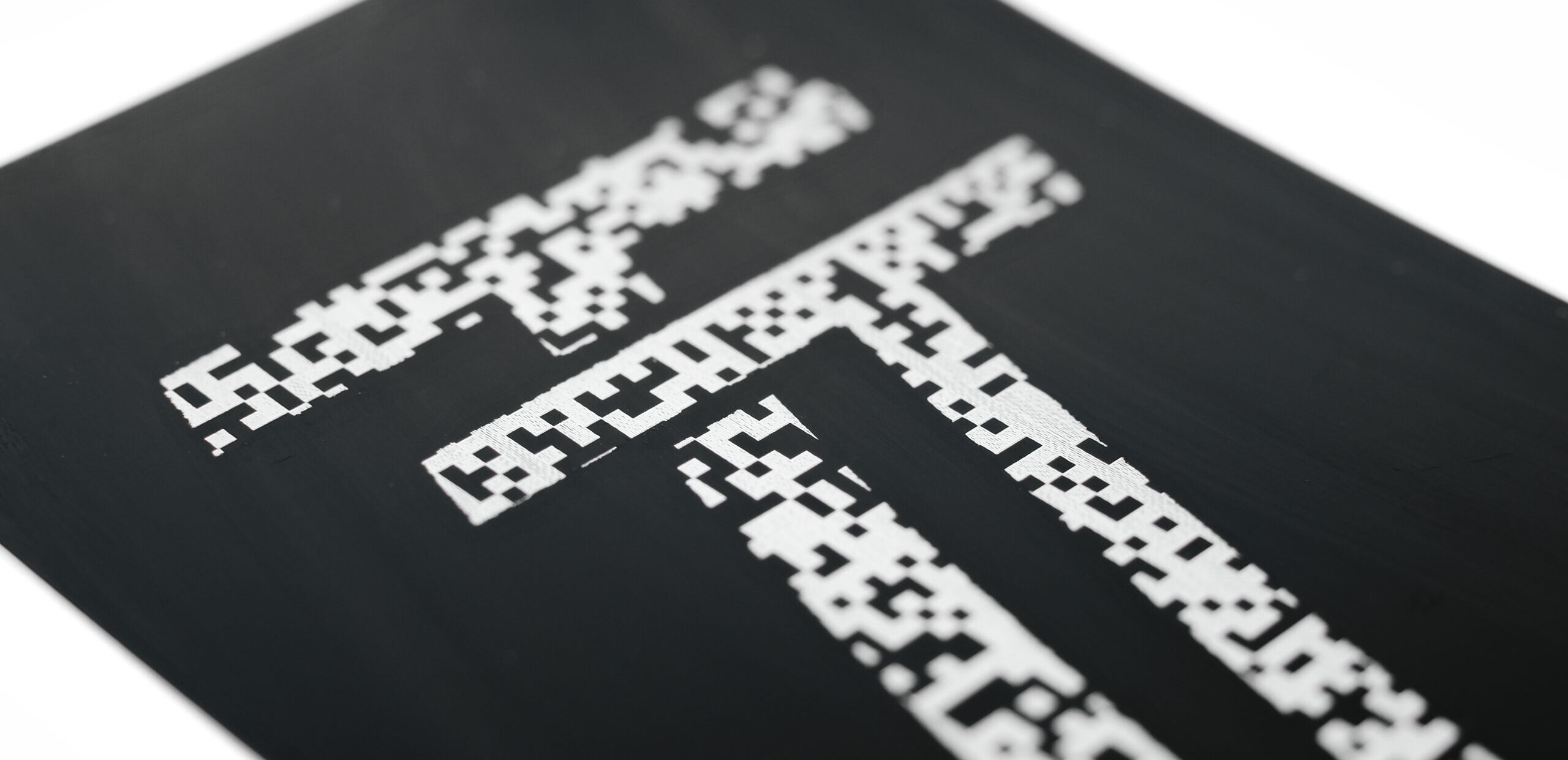

Laser marking: accuracy to the nearest micron

Precision is the essence of laser marking, making it the ideal technological solution for businesses looking for quality and accurate marking. The level of detail provided by laser beam marking makes it possible to engrave textual elements in small or even discreet dimensions (in particular for the fight against counterfeiting and the parallel market).

Unalterable quality with laser marking

Laser marking withstands the most extreme environmental conditions, daily wear and tear and frequent handling, without deteriorating its readability and long-term quality.

Laser marking to keep up a good production rhythm

Laser marking allows you to maintain your production rate.

Thanks to its speed of completion, you get a rapid result without compromising your line. With the laser process, production combines performance, reliability and efficiency.

With laser marking, each engraving becomes a symbol of your quality and enhances the image of your company. Its precision and durability boost your reputation. THEMIS Technologies helps you achieve your goals by developing the solution you need.

Documents to download

Download our comparisons on the different marking solutions

Contact an expert

Contact our laser expert for any questions.

M. François-Eudes LEFEVRE

+33 761 419 057How does laser marking work?

Is laser marking suitable for all materials?

What are the possible applications of laser marking?

Does laser marking damage products?

Is laser marking resistant to environmental conditions?

Is laser marking suitable for small parts or complex surfaces?

Is laser marking compatible with traceability standards?

Is laser marking an environmentally friendly solution?

How do I choose the right laser marking system for my application?