As an expert in laser industrial solutions, THEMIS Technologies designs and integrates laser cutting machines for all sectors

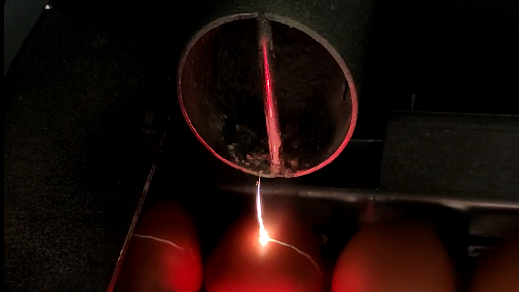

The passionate men and women who make up our teams develop technological solutions that provide a comprehensive response to our customers' requirements.With laser cutting, the material is subjected to a high-energy beam which, by releasing intense heat, melts and vaporises almost all material. Particularly used in micro-machining and sheet metal processes of various thicknesses, laser cutting supports, among others, the automotive and aeronautical industries or sectors that produce high-tech parts or products.

Clean and fast laser cutting

It is no longer necessary to choose between speed and precision: laser cutting is a technology that offers both exceptional accuracy and high speed of execution. This cutting method uses a highly concentrated beam which allows sharp, precise and high-quality cutting on a wide variety of materials.

Laser technology is ideal for industries that use particularly small parts, since it allows an accuracy of up to 0.1 mm. The laser beam can move quickly over the surface of the material, even when complex. Compared to other cutting methods, laser cutting significantly reduces production time.

Use laser to cut all your materials

Laser technology is capable of cutting a wide range of materials, making it a versatile method, widely used in different industries. Steel, aluminium, stainless steel, brass or copper, glass and textiles require precise cutting. This is particularly the case in the automotive parts industry, aerospace, electronics industry or any metal processing industry. It is also used for making prototypes in different materials, which facilitates the design and product development process.

Laser cutting can also be applied to wood, fabrics, glass, plastics and polymers, in all sectors.

Clean laser cutting at no extra cost

As well as cutting cleanly, the laser beam does not need to be in contact with the material it is cutting.

This reduces the risk of deterioration or deformation on the workpiece. In addition, the laser beam, being extremely precise, generates very little loss of material. There is no need for chemicals or cutting fluid: the laser beam is a clean technology that reduces the environmental impact of the industries that use it.

Where other processes require the installation of additional tooling as required, laser cutting does not incur any additional costs for equipment or regular purchases of consumables.

With laser cutting, you optimise your production by offering high cutting speed without compromising on quality. THEMIS Technologies supports your company from the design of your tailor-made solution to the integration of the machine on your line.

Documents to download

Download our comparison on laser cutting and punching solutions

Contact an expert

Contact our laser expert for any questions.

M. François-Eudes LEFEVRE

+33 761 419 057How does laser cutting work?

What are the advantages of laser cutting over other cutting methods?

What parameters can be adjusted on the laser cutting machine?

What safety precautions are necessary when using laser cutting?

What materials cannot be cut by laser?

What is the maximum thickness that laser cutting can handle?