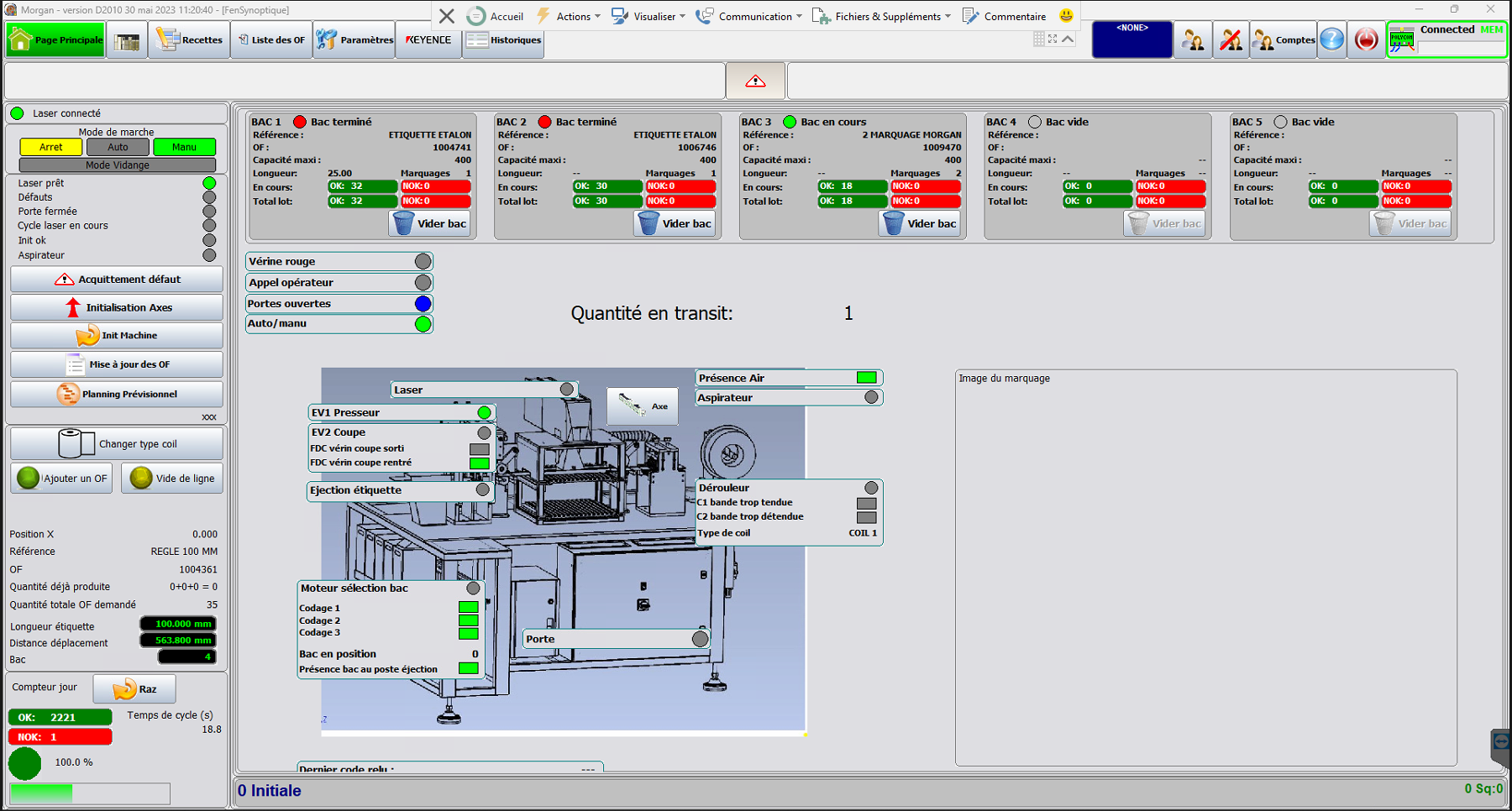

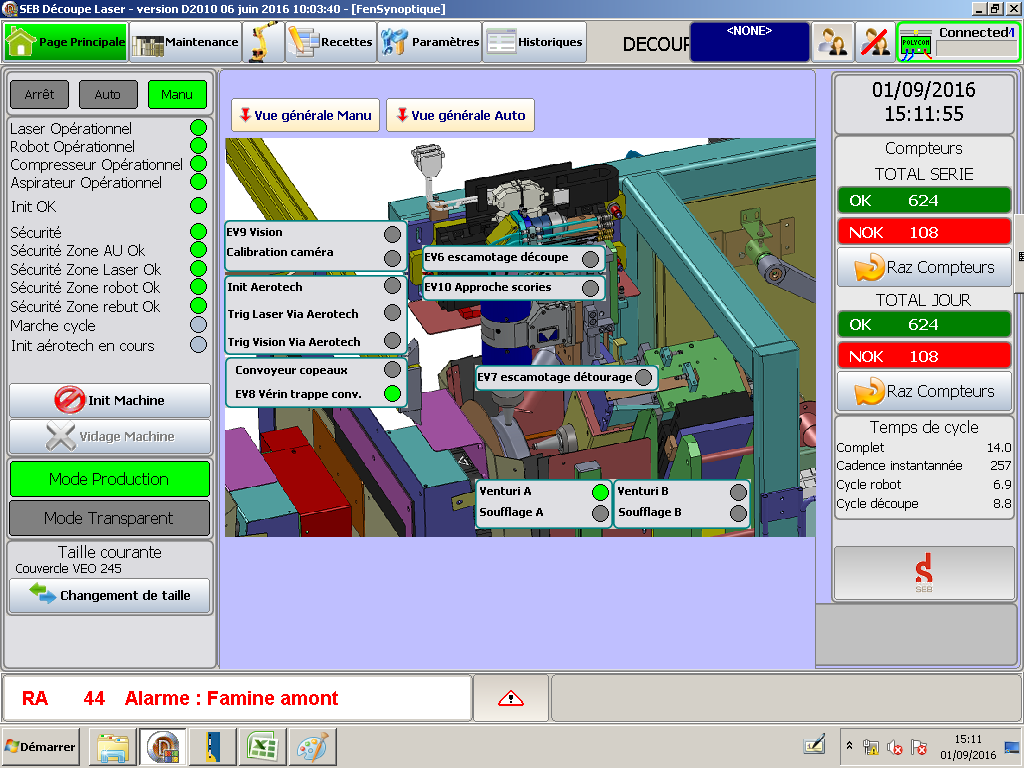

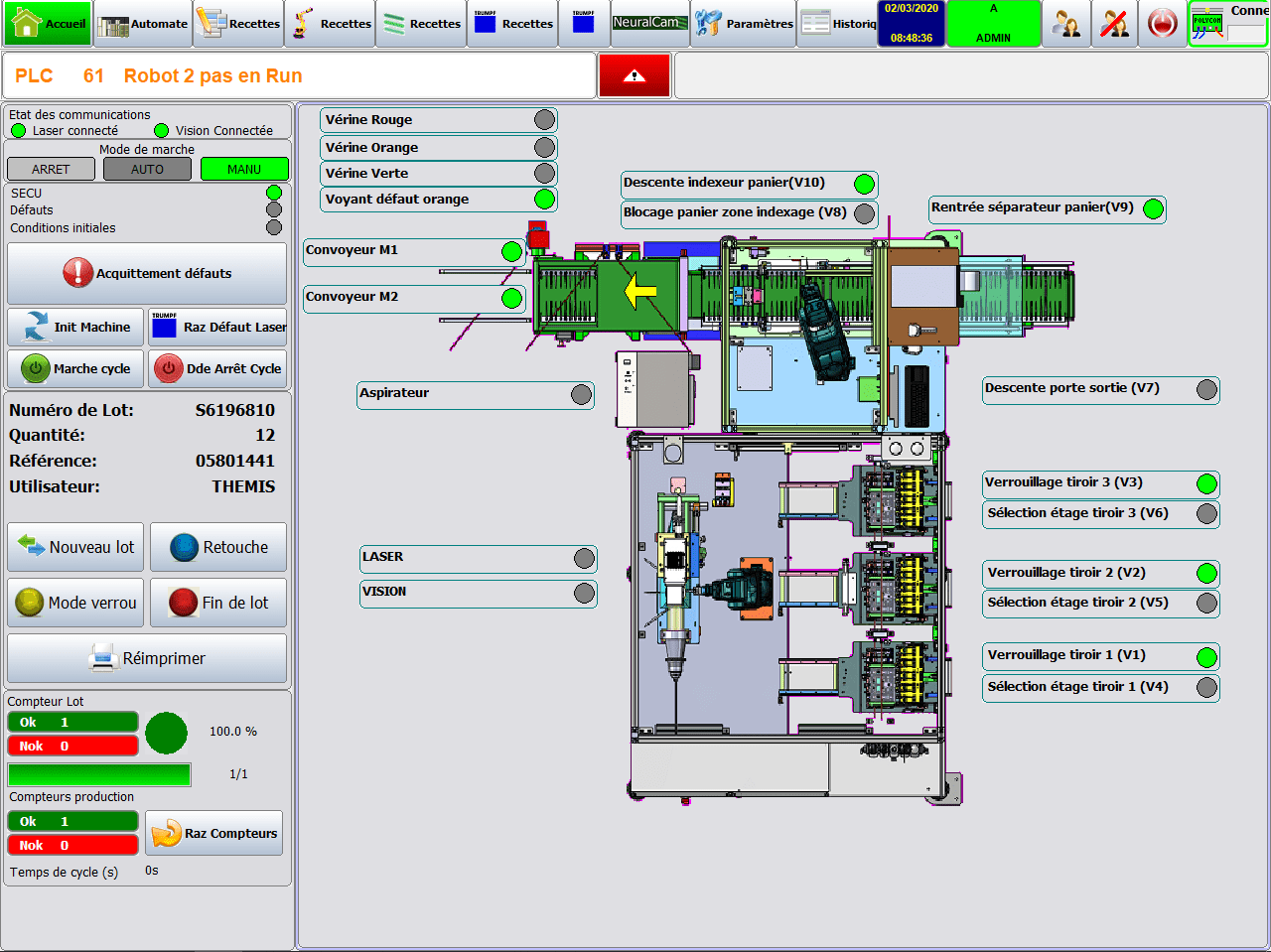

Easy access to the heart of your machine with your supervisor software

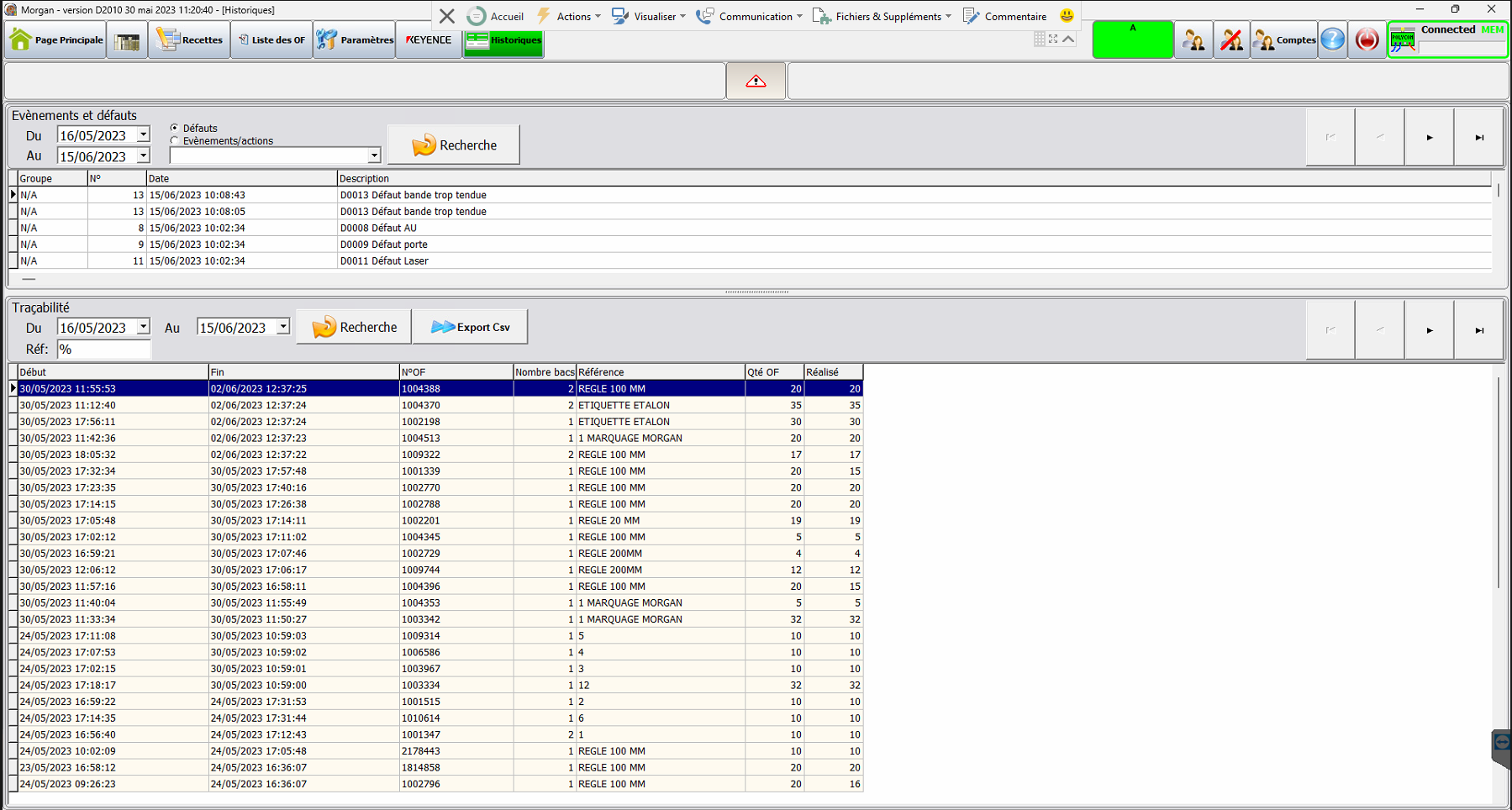

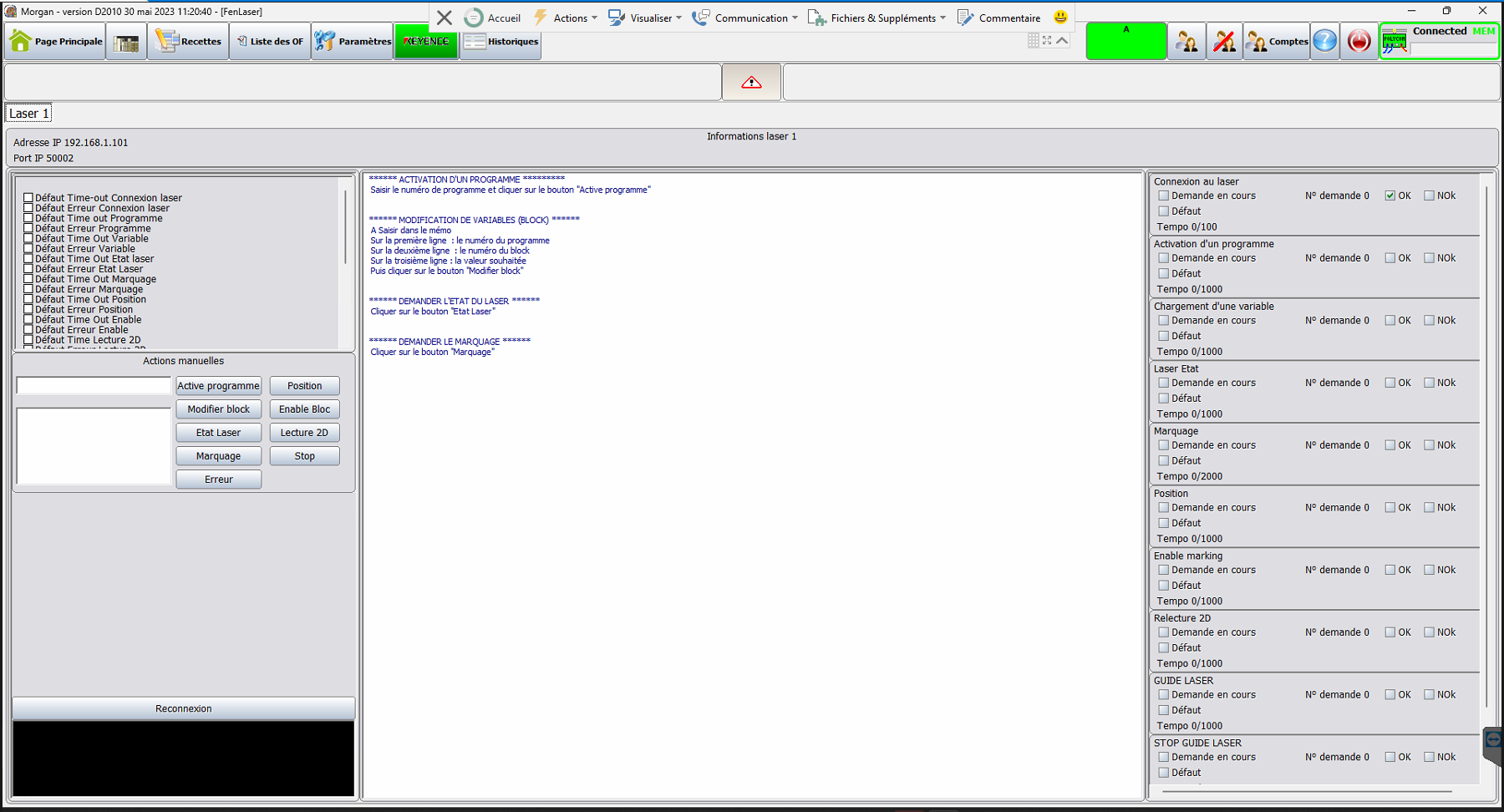

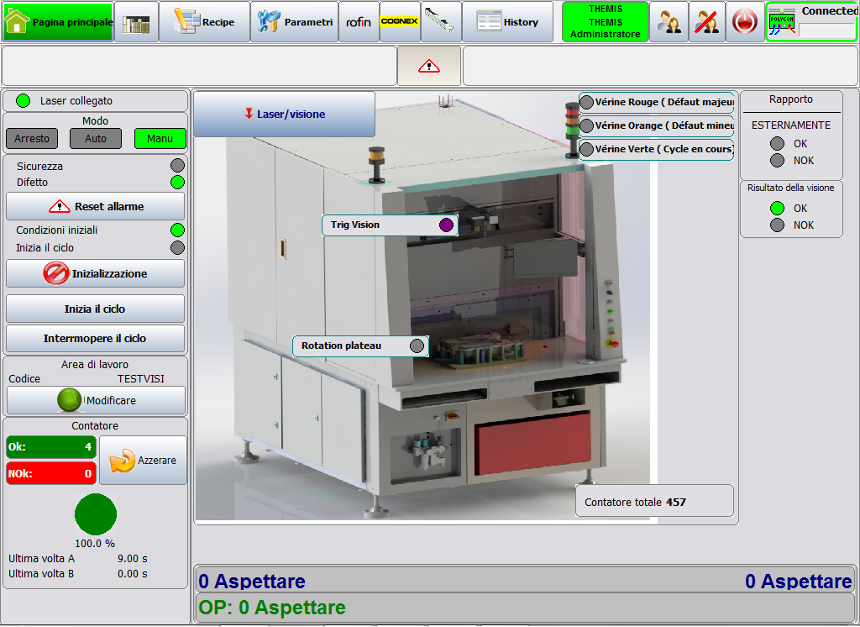

Take control of your production at all times and keep an overview with your supervisor software. It is the actual nerve centre of your machine and it helps you easily master every process and configure your equipment. Designed to be intuitive, the interface is easy to use for all your operators.Take control of all stages and all aspects of your machine - e.g. production rhythm, orientation, start or stop - to optimise your production. The information is made available to you, where you need it and in the appropriate format.

Software tailored to your teams and production line

Our laser machines are mostly designed and delivered with HMI and supervisor software. Our goal is to check only what needs checking. In other words, we develop supervision solutions according to your requirements. Each configuration is unique and your supervision software is adapted to your machine, the use you make of it and your team. Connect your machine to other machines in your line and communicate with other blocks or your company’s industrial network.

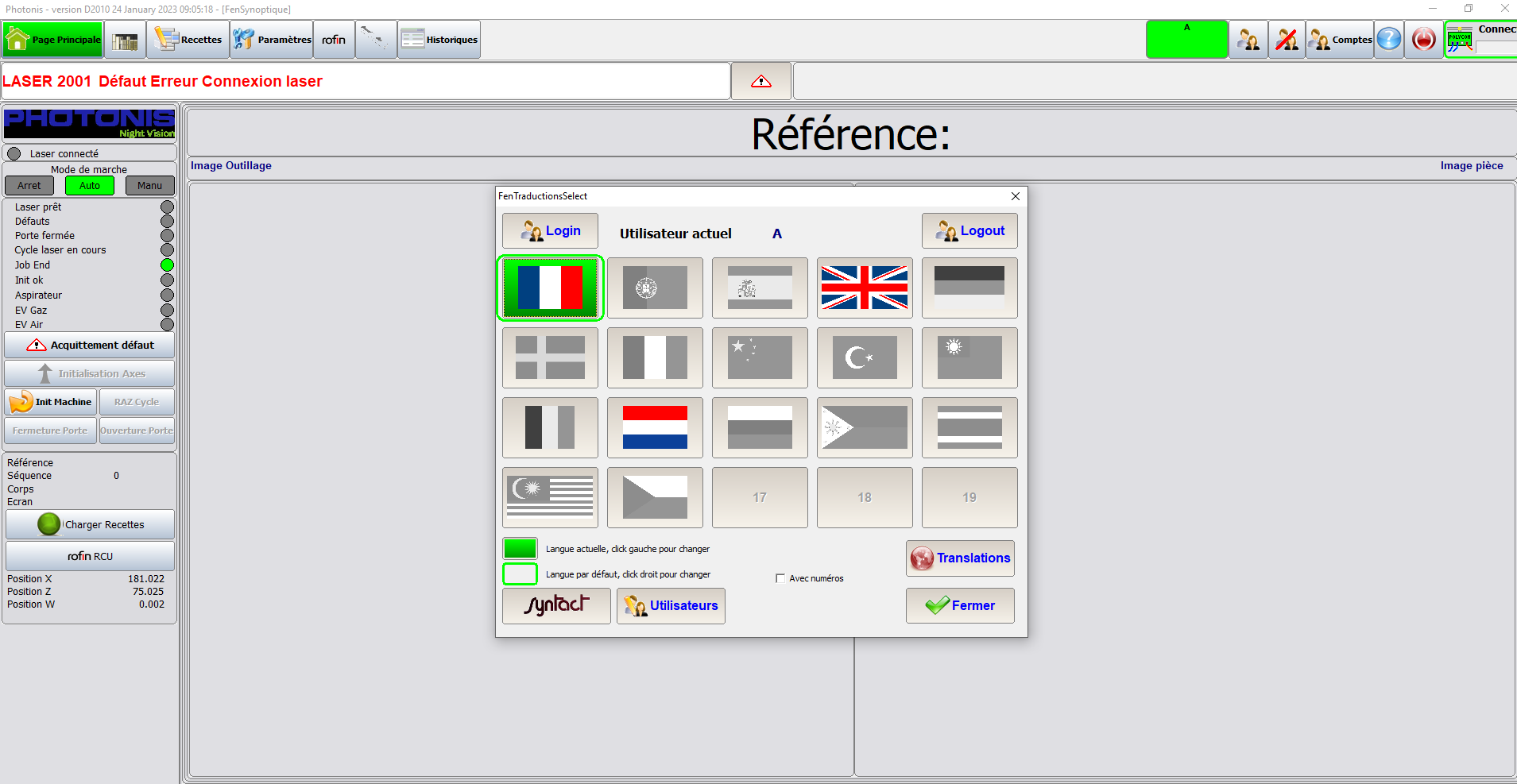

All our multi-language supervisors are developed to make it very easy for you to add users who evolve around your machine. Identify your employees in the settings and assign rights to each nominative profile according to the jobs and responsibilities held.

THEMIS Technologies industrial supervision software: the result of more than 25 years of evolution

To make machines that meet the requirements of our customers beyond their expectations, there is one single condition: listening to them. Our teams have constantly monitored the market for more than 25 years. They have collected many queries and responded to multiple industrial challenges. All the machines and software we develop are the result of a perpetual search for optimisation. The aim is to offer nothing but the best.

By collating relevant information, industrial supervision helps you to make and apply strategic decisions for your production. Our supervisory software supports you in your main objective: to meet today’s industrial challenges and grasp tomorrow’s opportunities.

Documents to download

Download our documentation on our industrial supervision solution

Contact an expert

Contact our laser expert for any questions.

M. François-Eudes LEFEVRE

+33 761 419 057What is industrial supervision ?

What role does an HMI play in industrial supervision ?

What types of data can be retrieved by a supervisor ?

What are the key features of supervision software ?

What are the advantages of customised industrial supervision software ?