Our Configurator

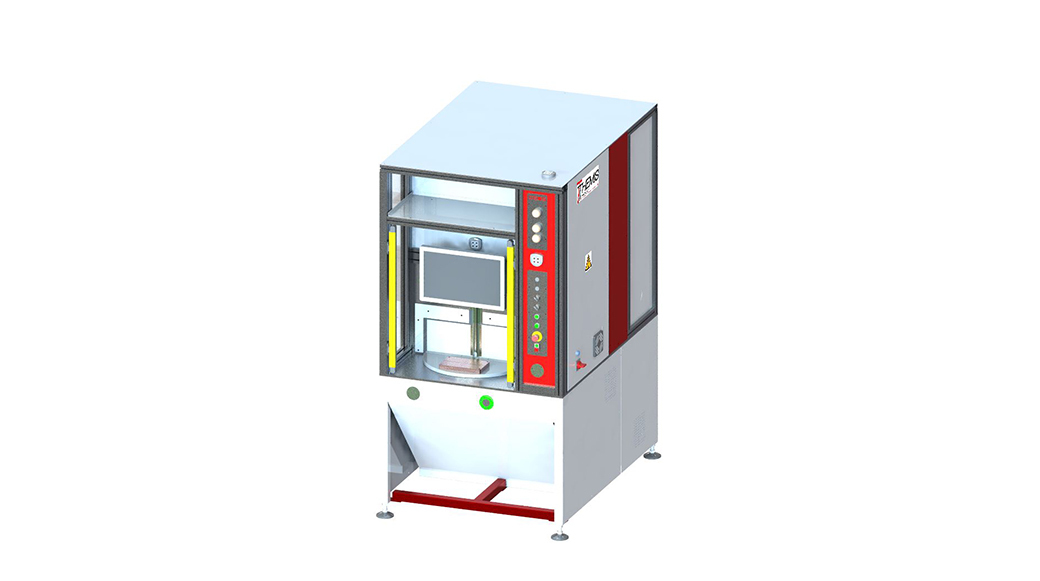

The right laser solution for your needs.

Our collective mission: meet your industrial challenges

THEMIS Technologies

Documents to download

Download the THEMIS Technologies presentation and our laser documentation.

Contact our laser experts

Call us

+33 247 524 300HOW TO FIND US

111 RUE MARC SEGUIN

ZA LES DEVANTS

37340 AMBILLOU FRANCE